Commercial Kitchen Fit-Out Costs: A Complete Guide for Smart Business Decisions

Planning a commercial kitchen fit-out? Understanding the costs involved is the first step to making smart decisions. This guide breaks down what you can expect to spend — and where you might be able to save.

Embarking on a commercial kitchen project represents one of the most significant investments any food service business will make. Whether you’re launching a new restaurant, upgrading an existing facility, or expanding your operations, having a clear understanding of the financial implications will help ensure your project stays on track and delivers the return on investment you’re seeking.

At Midlands Projects, we’ve guided countless clients through the commercial kitchen fit-out process across diverse sectors including restaurants, schools, hotels, and cafés. Our experience spanning over four decades has taught us that well-informed clients make better decisions, avoid costly surprises, and ultimately achieve more successful outcomes.

The commercial kitchen industry has evolved dramatically in recent years. Rising material costs, increasingly sophisticated equipment options, and stricter regulatory requirements have all influenced project budgets. However, with proper planning and expert guidance, businesses can still achieve exceptional results within their financial parameters.

Understanding Typical Cost Ranges

The investment required for a commercial kitchen fit-out varies considerably depending on several key factors: the size of your operation, the complexity of your menu offerings, the level of equipment specification you require, and your specific sector requirements.

Small café kitchens generally cost between £20,000 and £40,000. These compact operations typically serve a limited menu with basic food preparation requirements. A café kitchen might include essential equipment such as commercial coffee machines, grills, refrigeration units, and basic preparation areas. The smaller footprint means lower costs for ventilation systems, electrical work, and flooring, making these projects more accessible for independent operators and start-up businesses.

Medium-sized restaurant kitchens can range from £50,000 to £80,000. These facilities require more sophisticated equipment to handle diverse menu offerings and higher customer volumes. Restaurant kitchens typically need commercial-grade ovens, multiple cooking stations, extensive refrigeration systems, dishwashing equipment, and comprehensive food preparation areas. The increased complexity and equipment specifications drive costs higher, but these investments are essential for delivering consistent quality and meeting customer expectations.

Large-scale kitchens for schools or hotels often exceed £90,000. These substantial operations serve hundreds or thousands of meals daily, requiring industrial-grade equipment, extensive preparation areas, and complex ventilation systems. School kitchens must meet specific nutritional and safety standards, while hotel kitchens often need to accommodate multiple dining outlets with varying requirements. The scale and complexity of these projects necessitate significant investment, but they’re designed to serve large populations efficiently over many years.

These cost ranges reflect complete fit-out projects including design, equipment, installation, and essential ancillary work. However, every project is unique, and actual costs will depend on your specific requirements, site conditions, and equipment choices. Working with experienced professionals from the outset helps ensure realistic budget expectations and prevents costly surprises during the project.

Breaking Down the Main Cost Categories

Understanding how your budget will be allocated across different project elements helps you make informed decisions about where to invest and where you might find savings opportunities. The overall cost typically breaks down into five key areas, each playing a crucial role in your kitchen’s success.

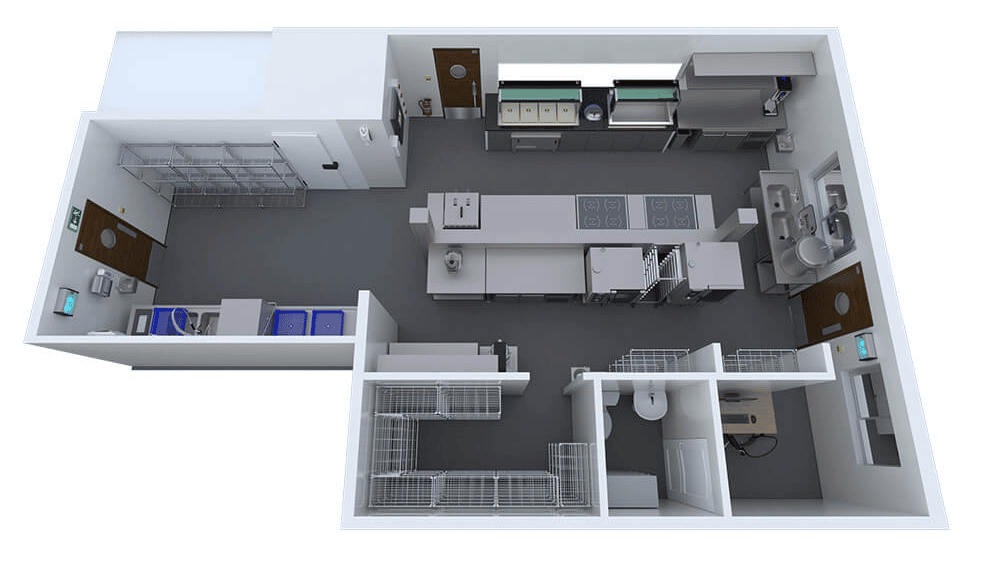

Design and consultancy fees account for around 10–15% of the budget. This investment covers the expertise needed to create an efficient, compliant, and future-ready kitchen design. Professional designers bring invaluable experience in workflow optimisation, equipment selection, and regulatory compliance. They create detailed 2D and 3D CAD drawings that help visualise your space and identify potential issues before construction begins. While this might seem like a significant upfront cost, quality design work prevents expensive mistakes and ensures your kitchen operates efficiently from day one.

Equipment makes up the largest share at 30–50% of your total investment. This category encompasses everything from cooking equipment and refrigeration units to food preparation machinery and dishwashing systems. The wide percentage range reflects the variety of equipment options available, from basic commercial-grade appliances to high-end, technologically advanced systems. Your equipment choices should align with your menu requirements, expected volume, and long-term business goals. Investing in quality equipment from reputable manufacturers ensures reliability, efficiency, and longevity.

Ventilation systems usually take 10–20% of your budget. Proper ventilation is non-negotiable in commercial kitchens, both for regulatory compliance and staff comfort. Modern ventilation systems do more than extract cooking odours and steam; they maintain air quality, control temperature, and contribute to energy efficiency. The percentage varies depending on your kitchen’s size, the type of cooking you’ll be doing, and your building’s existing infrastructure. Complex operations requiring sophisticated fire suppression systems or those in challenging locations may see higher ventilation costs.

Labour and installation fall between 15–25% of your total spend. This covers the skilled tradespeople needed to bring your design to life: electricians, plumbers, gas engineers, and installation specialists. The percentage depends on the complexity of your project and any structural modifications required. While it might be tempting to reduce costs here, quality installation is crucial for equipment performance, safety, and longevity. Properly installed systems require less maintenance and operate more efficiently, providing long-term savings.

Finishes like flooring and walls represent 5–15% of your total spend. These elements might seem secondary, but they play crucial roles in hygiene, safety, and durability. Commercial kitchen finishes must withstand constant cleaning, temperature fluctuations, and heavy use while maintaining their appearance and functionality. Quality finishes reduce maintenance costs and help maintain the professional appearance essential for customer confidence and staff morale.

Hidden Costs to Consider

Even with careful planning, commercial kitchen projects often involve additional expenses that aren’t immediately obvious. Being aware of these potential costs helps you budget more accurately and avoid unwelcome surprises.

Planning permission applications might be required, particularly if you’re changing the use of a building or making structural modifications. Local authority fees vary, but you should budget for both the application costs and any required supporting documentation such as structural reports or environmental assessments. The process can take several weeks, so factor this into your project timeline.

Temporary kitchen setups during installation can be necessary to maintain business operations. If you can’t afford to close completely during your fit-out, you might need to rent temporary equipment or arrange alternative preparation facilities. This ensures continued revenue but adds to your project costs. Planning the installation sequence carefully can minimise disruption and reduce temporary arrangements.

Staff training before reopening is essential but often overlooked in initial budgets. New equipment and layouts require staff familiarisation to ensure safe, efficient operation. Factor in the cost of training sessions, potential productivity losses during the learning period, and any specialist training required for sophisticated equipment.

Utility upgrades might be necessary to support your new equipment. Older buildings may need electrical system upgrades, gas supply modifications, or water pressure improvements. These costs can be substantial but are essential for safe, efficient operation.

Licensing and certification fees for various aspects of your operation, from food hygiene certifications to equipment warranties, should be included in your planning.

Proven Tips to Stay on Budget

Successful commercial kitchen projects require careful planning and strategic decision-making. These proven strategies can help control costs while ensuring you achieve your operational goals.

Work with a company that handles both design and installation. This integrated approach offers several advantages: improved communication, clearer accountability, and often better pricing through established supplier relationships. When one company manages the entire project, there’s less potential for miscommunication between designers and installers, reducing the risk of costly errors or delays.

Consider leasing equipment instead of buying it outright. Leasing can significantly ease upfront costs, preserving your working capital for other business needs. Modern leasing agreements often include maintenance packages, ensuring your equipment stays in optimal condition while providing predictable monthly costs. This approach is particularly attractive for technology-heavy equipment that may benefit from regular upgrades.

Consider phasing your kitchen upgrade in stages if necessary. This approach allows you to spread costs over time while maintaining operations. Start with essential equipment and systems, then add enhancements as cash flow permits. Careful planning ensures each phase delivers operational benefits while building toward your complete vision.

Invest in energy-efficient equipment despite higher upfront costs. Modern equipment offers significant operational savings through reduced energy consumption, often paying for itself within a few years. Many energy-efficient appliances also qualify for government incentives or rebates, further improving the return on investment.

Plan for contingencies by setting aside 10-15% of your budget for unexpected costs. Commercial kitchen projects often reveal unforeseen issues such as structural modifications or utility upgrades that weren’t apparent during initial planning.

Making Your Investment Work

A well-planned commercial kitchen fit-out is an investment in your business’s future success. The key to maximising this investment lies in working with experienced professionals who understand both the technical requirements and business realities of commercial food service.

Quality design and installation create kitchens that operate efficiently, meet regulatory requirements, and adapt to changing business needs. While the initial investment might seem substantial, a properly executed project delivers years of reliable service, supporting your business growth and profitability.

Remember that the cheapest option rarely represents the best value. Focus on achieving the right balance between cost and quality, ensuring your new kitchen supports your operational goals while staying within your financial parameters.

At Midlands Catering Projects, we understand that every commercial kitchen project represents a significant investment. Our comprehensive approach, from initial consultation through final installation, ensures you achieve maximum value from your investment while creating a kitchen that serves your business effectively for years to come.

Making healthy decisions

By implementing a hygienic commercial kitchen design from the start, you can easily increase its efficiency, lower cleaning times and reduce your staff’s exposure to chemicals. It’s an important investment and one that we can help you with. For more information, please get in touch.

Share this article: